Projects

Ferretti International is a well-resourced, diversified engineering and fabrication company with an enviable track of completing major industrial projects in the Defence, Energy, Oil & Gas and Infrastructure sectors across Australia. Learn about some of our major completed projects.

Maritime Construction – Whyalla Jetty

Ferretti International scope included the surface treatment of the steel piles, workshop fabrication drawings, supply material, fabricate the structural steel, fabricate all balustrading, fabricate all shelters and surface treatment.

Projects for heavy industry

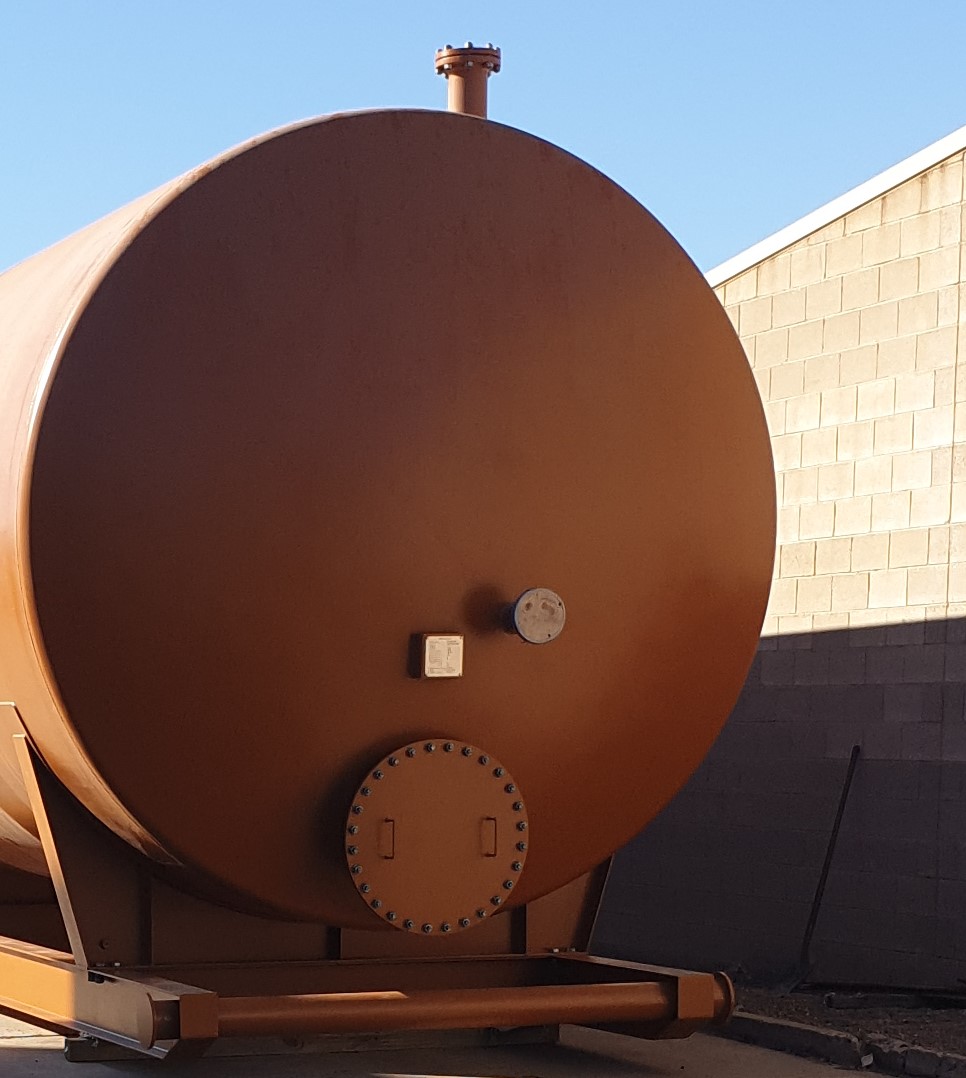

Central Petroleum

Oily water tank and pipe spools fabrication

Ferretti was engaged by Central Petroleum to replace the oily water tank and the piping on the skid. Ferretti International scope was to supply all material, fabricate the tank, skid and piping.

The tanks and piping were painted internally and externally, and then spark tested to suit the required standards.

GFG Alliance – LIBERTY Primary Steel

Ferretti International’s scope of work was to fabricate 2 off Ladles which included the supply of material, rolling of the barrels, full assembly of the Ladle, NDT of the ladles and PWHT of the completed Ladles.

BHP

BHP SAF Piping

Ferretti International’s scope was to supply the SAF material, fabricate spooling to BPH drawing, Hydro testing and clean the piping.

BHP Rubber Line Spool

Ferretti International’s scope was to supply all material, fabricate spooling to BHP drawing, NDT, Hydro testing, rubber lining and surface treatment.

GLP Warming Skid

Ferretti International’s scope of work was to:

- Supply of all structural materials (including structural fasteners) and labour to fabricate the base frames, including any platforms, ladders and handrails (where applicable)

- Supply of all piping materials as listed on the GLP isometric drawings. This scope shall include supply of gaskets and fasteners for the package.

- Fabrication of complete pipe spooling in accordance with GLP isometric drawings (after trial fitting). Piping fabrication shall be conducted in strict compliance with the nominated piping code and specifications.

- Trial install free issued equipment onto skid base, install all piping as welded trial assembly, trial assemble all structural pipe supports.

- Disassembly of all skid components prior to surface treatment.

- Surface treatment of structural steel components.

- Full assembly of skid including installation of vessels, pipe spools and structural steel .